Deep in Sweden’s cool north sits a diminutive factory the save the country’s largest industrial gamers non-public been progressively validating a brand unique know-how that might per chance neat up one in every of the dirtiest industries on Earth.

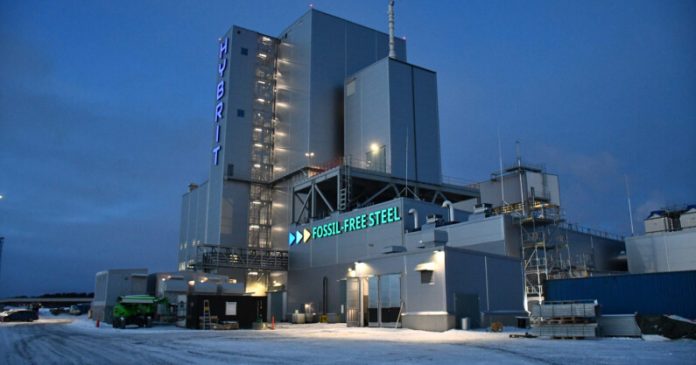

Vitality giant Vattenfall, steel-maker SSAB, and mining agency LKAB built the flexibility — located in the diminutive town of Luleå — in 2020, as allotment of the HYBRIT mission. The initiative objectives to demonstrate that steel would be made on an industrial scale using hydrogen and neat electricity.

“Utilizing hydrogen to manufacture steel is composed in its very early stages,” an SSAB representative told TNW. “It represents most efficient a diminutive allotment of nowadays’s steel production.” But that would be about to replace.

How place you assemble steel using hydrogen?

Steel is one in every of the sector’s most ancient provides. And its production is in administration of 11% of global CO2 emissions. These kinds of emissions are produced when heating and lowering iron — the core factor of steel — in a blast furnace using coal and coke (a polished form of coal, now not the soft drink).

The HYBRIT know-how, on the other hand, doesn’t exercise a blast furnace in any admire. It makes exercise of hydrogen as a replace of coke in a job known as explain bargain. This reduces iron oxides to metallic iron with out melting it.

The hydrogen reacts with the oxygen in iron ore, producing so-known as “sponge iron.” Basically the most efficient byproduct is water vapour.

At the plant in Luleå, SSAB takes this sponge iron after which melts it into steel in an electrical arc furnace powered by Vattenfall’s wind farms. The discontinue result’s appropriate ol’ approved steel — but with out the emissions.

Going mainstream

This week, Vattenfall, SSAB, and LKAB equipped the outcomes of their six-Three hundred and sixty five days trial to the Swedish Vitality Agency. The document reveals that the iron produced using hydrogen isn’t correct carbon neutral, but is also stronger and more sturdy than iron produced with fossil fuels. The partners non-public utilized for and received rather a lot of patents in line with the outcomes.

HYBRIT’s pilot plant is the sector’s first to demonstrate the “fossil-free value chain” for steel on a semi-industrial scale. The factory has already produced 5,000 tonnes of hydrogen-diminished iron. And companies cherish Volvo, Epiroc, and Peab non-public already save the inexperienced steel of their automobiles, machinery, and structures.

The economic giants will now start constructing an even bigger factory in Gällivare, three hours North of Luleå, in the coronary heart of Swedish Lapland. The prolonged-period of time thought is to make more hydrogen iron factories and completely decarbonise steel production in Sweden — slashing 10% of the international locations emissions.

Nonetheless, significant hurdles lie ahead. Producing sufficient portions of inexperienced hydrogen will require fixed provides of neat energy. Furthermore, hydrogen is on the moment basic dearer than fossil fuels, and the tag isn’t falling as like a flash as anticipated.

Can Europe raise on to its inexperienced steel tech?

Mining giant Archelor Mittal talked about in February that it can truly not operate its European vegetation using inexperienced hydrogen for the rationale that resulting inexperienced steel would now not compete on international markets. It’s simply too dear.

“Rising any completely unique know-how is costly,” an LKAB spokesperson told TNW. “With toughen, it goes quicker, but we are competing with initiatives that catch say backing at very a lot higher stages.”

LKAB is absolute self perception relating to the very fact that, oftentimes, local weather tech funding flows more freely start air Europe, fuelled by huge public spending cherish Biden’s $1 trillion Inflation Reduction Act.

In March, the US pledged up to $1bn for 2 inexperienced steel projects. US steelmaker Cleveland-Cliffs will make one in every of the vegetation. The different might per chance be constructed by none as a replace of SSAB, using the hydrogen bargain know-how developed below HYBRIT.

European policymakers would place effectively to learn the writing on the wall and enhance funding for local weather tech — or grief continuing the constructing of forcing homegrown know-how to aged on international shores.

It’s now not all contaminated news, on the other hand.

H2 Inexperienced Steel, one in every of Europe’s most efficient funded startups, has chosen a local in Boden, Sweden, for its first industrial plant. The startup expects to roll out the first industrial batches of its steel by 2025 and objectives to manufacture 5 million tonnes of inexperienced steel a Three hundred and sixty five days by 2030.

H2 Inexperienced Steel has also signed an settlement with Iberdrola to make a plant powered by photograph voltaic energy in Spain, whereas GravitHy plans to start a hydrogen-primarily based entirely steel plant in France in 2027.